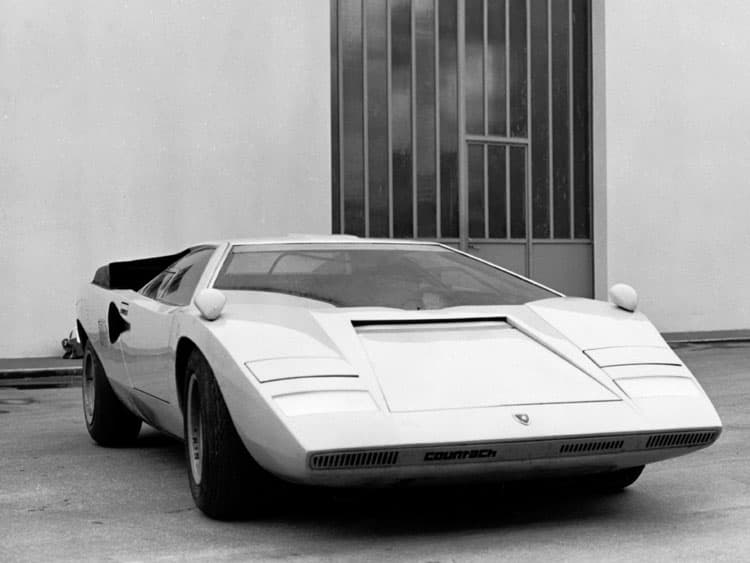

On the 1971 Geneva Auto Show Lamborghini introduced the mind-blowing Countach, the full denomination was LP 500 Countach, where the LP stood for Longitudinale Posteriore 5000 cc, and the 5-Liter engine was put longitudinally in the back.

This new 5-Liter engine, which was built using a lot of magnesium even for the gearbox and differential, was completely designed and built by Lamborghini, while Bertone, more precisely by Marcello Gandini, executed the body design.

At Lamborghini, Paolo Stanzani was responsible for the engineering, the transmission was put directly underneath the gear lever, so no complicated linkage was necessary for it, the gearbox was linked with the rear mounted differential through a long shaft in the bottom of the engine, the engine, gearbox and differential were mainly built from magnesium to reduce their weight.

The body styling was executed by Marcello Gandini, its upward and forward swinging doors were inspired on the Carabo, which was based on an Alfa Romeo chassis, these doors together with a periscope rear view mirror mounted in a tunnel in the roof were only a few of the main attractions on the Countach. The Countach looked awesome, a futuristic prototype, a one-off, but the critics were wrong, the Countach was destined to go into production, and shortly after the introduction, Ferruccio Lamborghini halted the Miura SV production, to be succeeded by the Countach. ‘Countach’ is in fact a Piedmontese dialect, and means something like stupendous, magnificent, splendid. There are several legends surrounding the origin of this name, but the official factory version is that it was Bertone’s first word when he saw the result of Gandini’s pen. Ferruccio Lamborghini himself was present at the time and decided that this name would fit the new Lamborghini perfectly.

This first Countach was a real show car, the dashboard did not have the normal analog instrumentation, but Bertone used experimental digital units, while a first edition of the check computer was installed, monitoring all the important areas of the car like the different fluids, the brakes, etc… Later when Bob Wallace was testing the LP500, he had the digital instrumentation replaced with normal ones. From the first moment on, the orders started coming in, at that time it was not even sure the car would actually be produced, but after Ferruccio saw how much people were willing to buy a Countach he decided to build it in small quantities. This first prototype, which was finished in a bright yellow, had only a short life, which was very hard. Various modifications were needed to transform the unique prototype into a production model, large air scoops were installed on top of the rear fenders to pull the air into the radiators, who were now mounted vertically.

In addition, a pair of NACA-ducts was cut behind the doors and various windshield wipers were tested, after several thousands of hard miles the car ended its life with a barrier crash test at MIRA in Britain.

After this first rolling prototype, two others were built to get the Countach into production, a red one that was still close to the original design but now with the big air intakes already built into the car from the start. On this red car, a test was performed with dual windscreen wipers, residing both to the left and right of the front windscreen, but this system proved to be inadequate under rain at high speeds.

This second prototype was also heavily tested by Bob Wallace during several circuit runs, but a third prototype was needed to be really able to get the Countach ready, this green example was later also used for the first official factory brochure offering the Lamborghini Countach LP400 as a production model, later another brochure was created with an actual yellow production car. This green car already featured the single windscreen wiper system that would be used on the actual LP400, the front bumper now was lowered a bit, and included driving lights like the LP400 would later on.

Both these late prototypes used the 4-Liter engine, which would be built into the actual production model, but the side window configuration of these prototypes never made it into production.